Applicable materials:Quartz stone, gold ore, iron ore, cement clinker, copper ore, pyrrhotite, magnetite and so on.

Free to visit the factory, the whole teaching style to assist the factory

Belt ball mill is a new type of energy-saving ball mill, which uses rubber belt and multi-stage pulley as transmission structure. Compared with the traditional gear ball mill, belt ball mill reduces energy consumption by 30%. Belt ball mill is mainly used for dry processing of ores, such as quartz sand, potassium feldspar, kaolin, aluminum ash, etc.

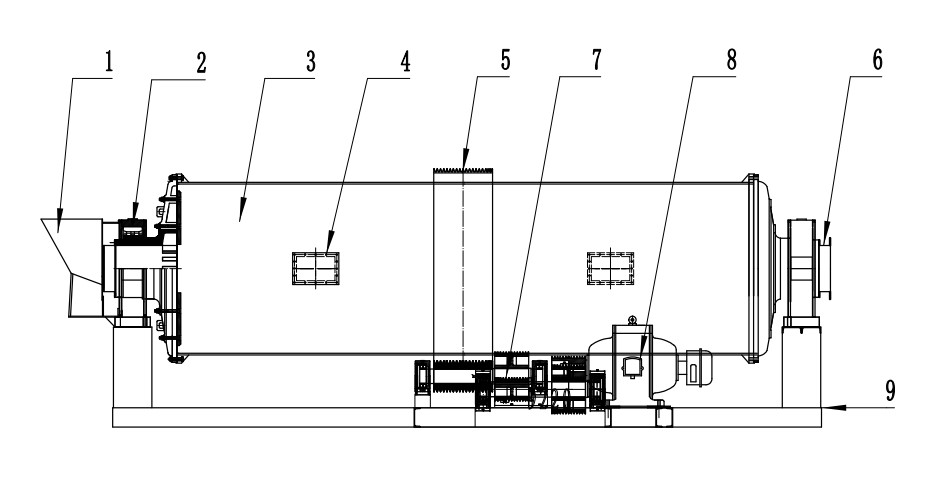

1.进料口 Inlet 2.轴承盒 Bearing box 3.筒体 Mill drum 4. 检修口 Access door 5. 大皮带轮 Large pulley groove 6.出料口 Outlet 7.多级调速皮带轮组 Multistage speed regulating pulley set 8.电机 Motor 9.机架 Frame

| 规格型号 | 筒体转速 (r/min) | 装球量 (t) | 进料粒度 (mm) | 出料粒度 (mm) | 产量 (t/h) | 电机功率 (kw) | 总重量 (t) |

| Ф1200×4500 | 32.4 | 5 | <25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

| Ф1500×3000 | 29.7 | 7.5 | <25 | 0.074-0.4 | 2-5 | 75 | 19.5 |

| Ф1500×4500 | 27 | 11 | <25 | 0.074-0.4 | 3-6 | 110 | 22 |

| Ф1500×5700 | 28 | 12 | <25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Ф1830×4500 | 25.4 | 15 | <25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

| Ф1830×6400 | 24.1 | 21 | <25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Ф1830×7000 | 24.1 | 23 | <25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Ф2100×7000 | 23.7 | 26 | <25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

| Ф2200×6500 | 21.7 | 35 | <25 | 0.074-0.4 | 14-26 | 280 | 61 |

| Ф2200×7000 | 21.7 | 35 | <25 | 0.074-0.4 | 15-28 | 380 | 62.5 |

| Ф2200×7500 | 21.7 | 35 | <25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Ф2400×7500 | 21 | 23 | <25 | 0.074-0.4 | 7-50 | 380 | 78 |

Steel slag recover metal plant into operation in Lianyungang City,Jiangsu Province

The activated carbon powder grinding and grading production line has been put into production

The steel slag recycling metal iron production line is operating in Baotou, Inner Mongolia

Polishing mill is working to remover the inpurity of scraps

Steel scraps polishing plant. Steel scraps purify plant

Using rod mill to process steel slag in Nanyang City