Applicable materials:Quartz stone, gold ore, iron ore, cement clinker, copper ore, pyrrhotite, magnetite and so on.

Free to visit the factory, the whole teaching style to assist the factory

Ball mill is the key equipment for grinding ore after crushing. It is widely used in industries of mineral, ceramics, chemical, cement, construction material, refractories, glass and other industries. Customers can choose dry type ball mill or wet type ball mill according to the characteristics of processing materials.

The ball mill of our company is an energy-saving bearing ball mill, which can save 20~30% of energy compared with the traditional ball mill.

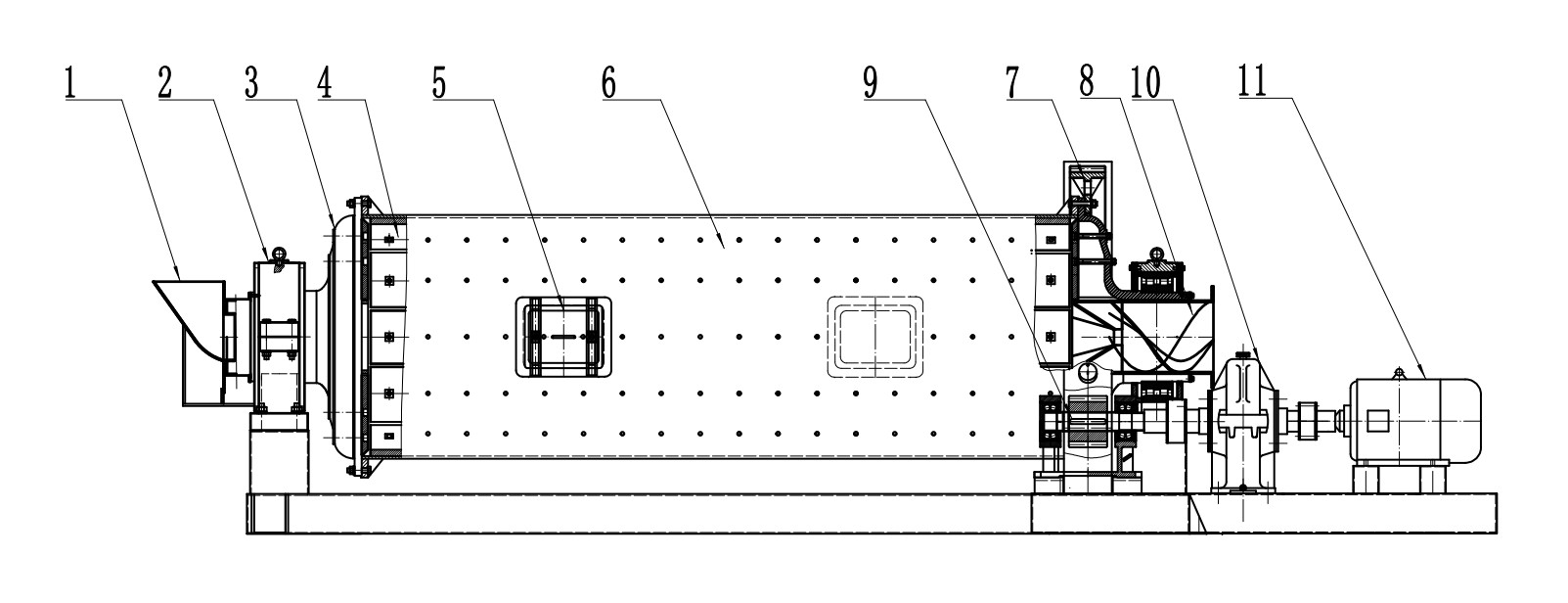

1.进料器 Inlet 2. Bearing box 3. 端盖 End cap 4.衬板Lining plate 5. 检修口 Access door 6.筒体 Mill drum 7. 大齿轮 big gear 8. 出料器 Outlet 9. 小齿轮 Small gear 10.减速机 Reducer 11. 电机 Motor

| 规格型号 | 筒体转速 (r/min) | 装球量 (t) | 进料粒度 (mm) | 出料粒度 (mm) | 产量 (t/h) | 电机功率 (kw) | 总重量 (t) |

| Ф900×1800 | 36-38 | 1.5 | <20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 |

| Ф900×3000 | 36 | 2.7 | <20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 |

| Ф1200×2400 | 36 | 3 | <25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 |

| Ф1200×3000 | 36 | 3.5 | <25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 |

| Ф1200×4500 | 32.4 | 5 | <25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

| Ф1500×3000 | 29.7 | 7.5 | <25 | 0.074-0.4 | 2-5 | 75 | 19.5 |

| Ф1500×4500 | 27 | 11 | <25 | 0.074-0.4 | 3-6 | 110 | 22 |

| Ф1500×5700 | 28 | 12 | <25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Ф1830×3000 | 25.4 | 11 | <25 | 0.074-0.4 | 4-10 | 130 | 34.5 |

| Ф1830×3600 | 25.4 | 13 | <25 | 0.074-0.4 | 4.5-10 | 155 | 36 |

| Ф1830×4500 | 25.4 | 15 | <25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

| Ф1830×6400 | 24.1 | 21 | <25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Ф1830×7000 | 24.1 | 23 | <25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Ф2100×3000 | 23.7 | 15 | <25 | 0.074-0.4 | 6.5-36 | 155 | 45 |

| Ф2100×3600 | 23.7 | 17 | <25 | 0.074-0.4 | 7-38 | 210 | 50 |

| Ф2100×4500 | 23.7 | 24 | <25 | 0.074-0.4 | 8-43 | 245 | 56 |

| Ф2100×7000 | 23.7 | 26 | <25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

| Ф2200×4500 | 21.5 | 27 | <25 | 0.074-0.4 | 9-45 | 280 | 54.5 |

| Ф2200×6500 | 21.7 | 35 | <25 | 0.074-0.4 | 14-26 | 380 | 61 |

| Ф2200×7000 | 21.7 | 35 | <25 | 0.074-0.4 | 15-28 | 380 | 62.5 |

| Ф2200×7500 | 21.7 | 35 | <25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Ф2400×3000 | 21 | 23 | <25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Ф2400×4500 | 21 | 30 | <25 | 0.074-0.4 | 8.5-60 | 320 | 72 |

| Ф2700×4000 | 20.7 | 40 | <25 | 0.074-0.4 | 22-80 | 380 | 95 |

| Ф2700×4500 | 20.7 | 48 | <25 | 0.074-0.4 | 26-90 | 480 | 102 |

| Ф3200×4500 | 18 | 65 | <25 | 0.074-0.4 | 按工艺条件定 | 630 | 149 |

| Ф3600×4500 | 17 | 90 | <25 | 0.074-0.4 | 按工艺条件定 | 850 | 169 |

| Ф3600×6000 | 17 | 110 | <25 | 0.074-0.4 | 按工艺条件定 | 1250 | 198 |

| Ф3600×8500 | 18 | 131 | <25 | 0.074-0.4 | 45.8-256 | 1800 | 260 |

Steel slag recover metal plant into operation in Lianyungang City,Jiangsu Province

The activated carbon powder grinding and grading production line has been put into production

The steel slag recycling metal iron production line is operating in Baotou, Inner Mongolia

Polishing mill is working to remover the inpurity of scraps

Steel scraps polishing plant. Steel scraps purify plant

Using rod mill to process steel slag in Nanyang City