Applicable materials:Screening or grading of iron ore, tin, tungsten, tantalum, niobium and other beneficiation plants.

Free to visit the factory, the whole teaching style to assist the factory

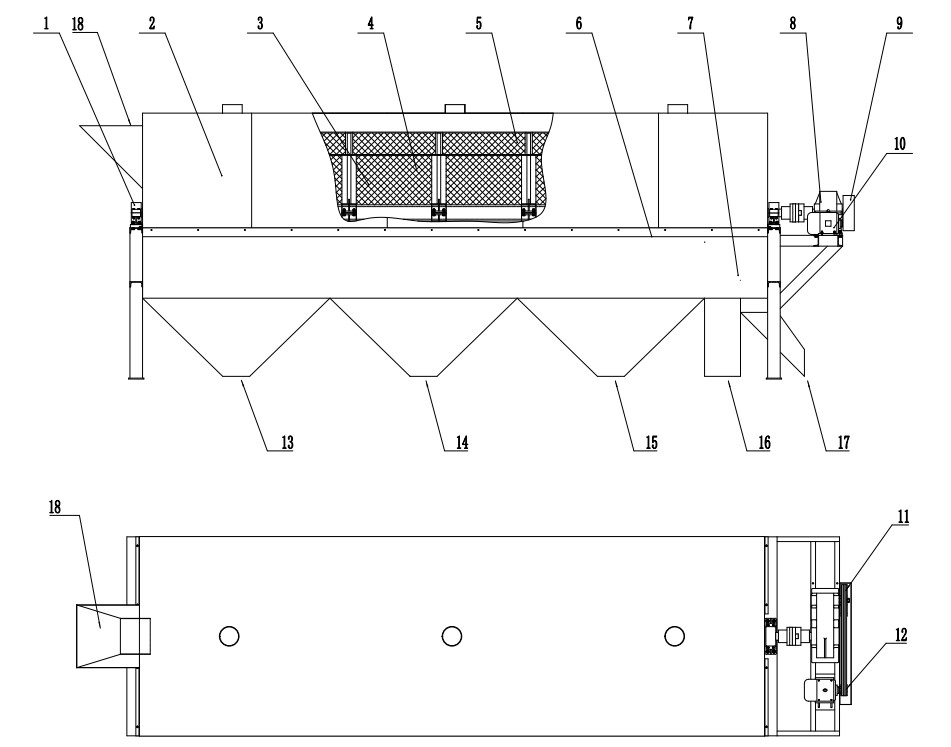

This rotary screen is a drum type screening equipment. The screen of the grading screen is wound around the framework into a circular shape, and the motor drives the circular screen to rotate. When materials pass through the screen, materials smaller than the fineness of the screen aperture leak out from the screen aperture, and materials larger than the fineness of the screen aperture flow out from the end of the screen, thereby achieving classification of materials with different particle sizes. One to five layers of screen can be installed inside the high-efficiency classification screen to achieve multi-level material screening operations.

1. Driven shaft 2. Upper cover 3. Sieve part 4. Inner sieve 5. Outer sieve 6. Frame 7. Lower cover 8. Reducer 9.Shield 10. Motor 11. Belt 12.motor pulley 13&14&15&16&17. Outlet

| Model | Diameter (mm) | Length (mm) | Cylinder speed (r/m) | Capacity (m³/h) | Power (KW) |

| Φ1300×4500 | 1300 | 4500 | 23 | 4-6 | 4 |

| Φ1300×5500 | 1300 | 5500 | 23 | 4-7 | 5.5 |

| Φ1500×6500 | 1500 | 6500 | 21 | 8-10 | 11 |

| Φ1800×6500 | 1800 | 6500 | 17 | 10-13 | 15 |

| Φ2000×6500 | 2000 | 6500 | 15 | 13-15 | 18.5 |

| Φ2200×6500 | 2200 | 6500 | 14 | 15-20 | 22 |

Jaw Crusher

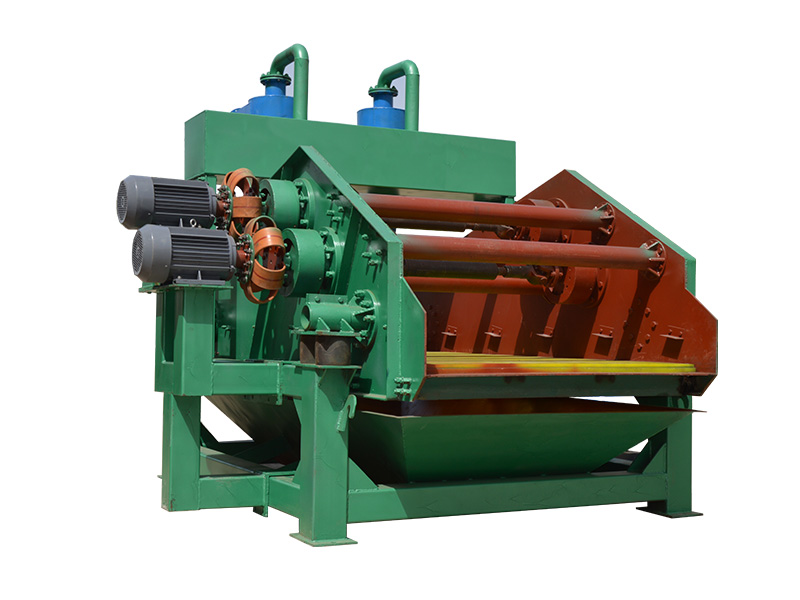

Aluminum Dross Rotary Screen

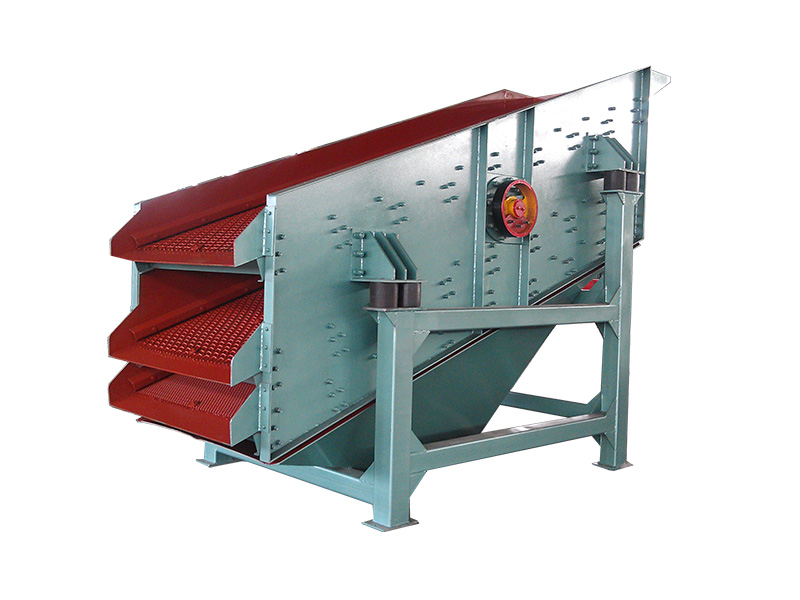

Linear Vibrating Screen

YK Series Circular vibrating Screen

Steel slag recover metal plant into operation in Lianyungang City,Jiangsu Province

The activated carbon powder grinding and grading production line has been put into production

The steel slag recycling metal iron production line is operating in Baotou, Inner Mongolia

Polishing mill is working to remover the inpurity of scraps

Steel scraps polishing plant. Steel scraps purify plant

Using rod mill to process steel slag in Nanyang City