Applicable materials:Magnetite, magnetic pyrite, roasted ore, ilmenite and other materials with particle size less than 3mm, as well as coal, non-metallic ore, building materials and other materials to remove iron.

Free to visit the factory, the whole teaching style to assist the factory

The wet type magnetic separator is mainly used for sorting magnetic materials, utilizing the magnetic difference between magnetic materials and non-magnetic waste to perform magnetic sorting within the equipment.

The magnetic system of wet type magnetic separator is composed of strontium ferrite magnetic blocks. The magnetic polarity alternates along the circumference. The magnetic envelope angle is related to the number of magnetic poles, the width of the pole surface, and the width of the pole gap, usually between 106 and 135 degrees. The magnetic system deviation angle is 15-20 °, and the magnetic system deviation angle can be adjusted.

The groove of the permanent magnet wet magnetic separator is a semi-inverse manifold. This machine is mainly used for coarse and fine selection of magnetic materials such as iron ore and steel slag.

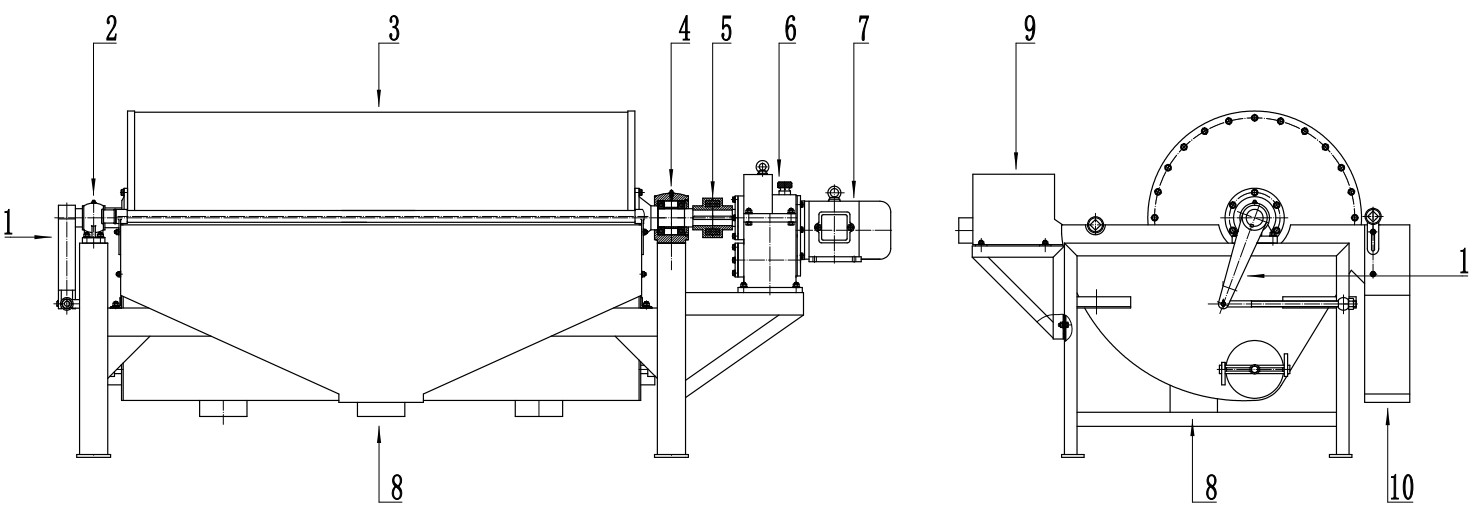

1.调节杆 Adjusting lever 2&4 轴承盒 Bearing boxes 3. 不锈钢外壳 Stainless steel cylinder 5. 联轴器Coupling magnet 6. 减速机 Reducer 7. 电机 Motor 8.尾矿出料口 Tailings discharge outlet 9.进料口 Inlet 10.精矿出料口 Concentrate discharge port

| 型号 | 筒体直径(mm) | 筒体长度(mm) | 处理能力(t/h) | 功率(kw) | 外形尺寸L×W×H(mm) | 重量(t) |

| CTB612 | 600 | 1200 | 10-20 | 1.1 | 2030×1200×1140 | 1.5 |

| CTB618 | 600 | 1800 | 15-30 | 2.2 | 2630×1200×1140 | 1.8 |

| CTB718 | 750 | 1800 | 20-45 | 3 | 2690×1380×1330 | 2.2 |

| CTB918 | 900 | 1800 | 25-55 | 4 | 2730×1600×1550 | 2.9 |

| CTB924 | 900 | 2400 | 35-70 | 4 | 3330×1600×1550 | 3.6 |

| CTB1018 | 1050 | 1800 | 40-75 | 5.5 | 2800×1760×1750 | 4.3 |

| CTB1024 | 1050 | 2400 | 60-120 | 5.5 | 3200×1760×1750 | 5.2 |

| CTB1030 | 1050 | 3000 | 70-150 | 7.5 | 3950×1760×1750 | 6.3 |

| CTB1218 | 1200 | 1800 | 60-110 | 5.5 | 2850×1980×1940 | 5 |

| CTB1224 | 1200 | 2400 | 70-130 | 7.5 | 3450×1980×1940 | 6.4 |

| CTB1230 | 1200 | 3000 | 80-160 | 7.5 | 4050×1980×1940 | 7.8 |

| CTB1530 | 1500 | 3000 | 100-180 | 11 | 4230×2300×2350 | 9.2 |

| CTB1540 | 1500 | 4000 | 115-220 | 11 | 5230×2300×2350 | 10.5 |

Steel slag recover metal plant into operation in Lianyungang City,Jiangsu Province

The activated carbon powder grinding and grading production line has been put into production

The steel slag recycling metal iron production line is operating in Baotou, Inner Mongolia

Polishing mill is working to remover the inpurity of scraps

Steel scraps polishing plant. Steel scraps purify plant

Using rod mill to process steel slag in Nanyang City