Applicable materials:Quartz stone, gold ore, iron ore, cement clinker, copper ore, pyrrhotite, magnetite and so on.

Free to visit the factory, the whole teaching style to assist the factory

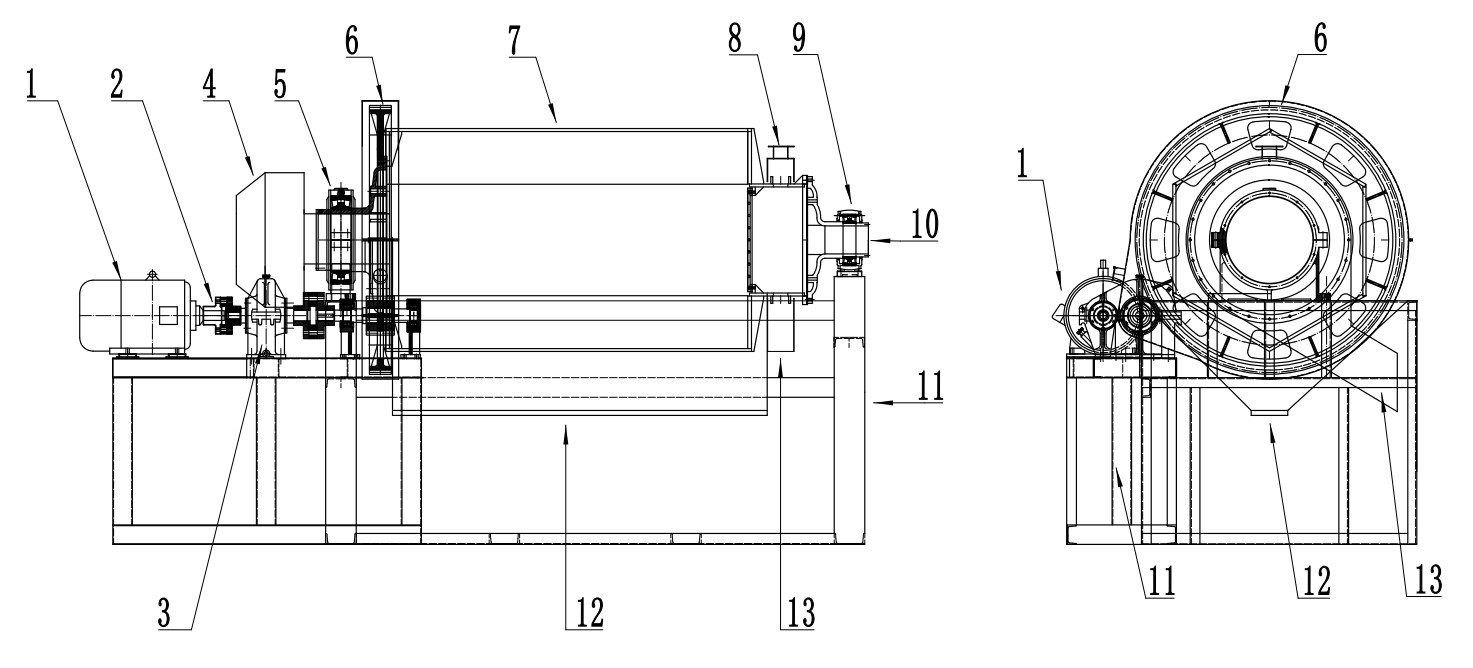

Polishing mill is a commonly used polishing equipment. The polishing mill is a horizontal structure, and the vertical section of the cylinder is a regular hexagonal shape. Under the drive of the motor, the polishing mill cylinder rotates, and the material is fed into the polishing mill through a feeder. The material undergoes a series of repeated movements of throwing up and falling down inside the cylinder. Under the collision of materials, impurities on the surface of the material are ground off, thereby improving the purity of the material. Due to the hexagonal structure of the polishing mill, significant centrifugal and impact forces are generated during the internal rotation of the material cylinder. Therefore, the polishing mill is often used as a crushing equipment to process casting slag and stainless steel slag.

1.电机 Motor 2. 联轴器 coupling 3.减速机 Reducer 4.进料器 Inlet 5.轴承盒 Bearing box 6. 大齿轮 Bull gear 7. 筒体 cylinder 8. 除尘器预留口 Reserved port for dust collector 9.轴承盒 Bearing box 10. 观察孔 Observation hole 11. 机架 Frame 12. 细料卸料口 Fine material discharge port 13.卸料口Discharge port

| 规格型号 | 筒体转速 (r/min) | 装球量 (t) | 进料粒度 (mm) | 出料粒度 (mm) | 产量 (t/h) | 电机功率 (kw) | 总重量 (t) |

| Ф900×3000 | 36 | 2.7 | <20 | <200 | 1.1-3.5 | 15 | 6.98 |

| Ф1200×3000 | 36 | 3.5 | <25 | <200 | 1.6-5 | 21.5 | 14.3 |

| Ф1200×4500 | 32.4 | 5 | <25 | <200 | 1.6-5.8 | 37 | 15.6 |

| Ф1500×3000 | 29.7 | 7.5 | <25 | <200 | 2-5 | 45 | 19.5 |

| Ф1500×4500 | 27 | 11 | <25 | <200 | 3-6 | 55 | 22 |

| Ф1830×3000 | 25.4 | 11 | <25 | 200 | 4-10 | 75 | 15 |

| Ф1830×4500 | 25.4 | 15 | <25 | <200 | 4.5-12 | 90 | 20 |

| Ф2200×4500 | 21.5 | 27 | <25 | <250 | 6-20 | 155 | 32.5 |

| Ф2400×3000 | 21 | 23 | <25 | <250 | 9-20 | 210 | 42 |

| Ф2400×4500 | 21 | 30 | <25 | <250 | 10-30 | 245 | 46 |

| Ф2700×4500 | 20.7 | 48 | <25 | <250 | 15-35 | 380 | 57 |

| Ф3200×4500 | 18 | 65 | <25 | <250 | 18-40 | 450 | 75 |

Steel slag recover metal plant into operation in Lianyungang City,Jiangsu Province

The activated carbon powder grinding and grading production line has been put into production

The steel slag recycling metal iron production line is operating in Baotou, Inner Mongolia

Polishing mill is working to remover the inpurity of scraps

Steel scraps polishing plant. Steel scraps purify plant

Using rod mill to process steel slag in Nanyang City